The Facts About Inventory Management Uncovered

The Buzz on Inventory Management

Table of ContentsThe 45-Second Trick For Inventory ManagementInventory Management Can Be Fun For AnyoneThe Best Guide To Inventory ManagementInventory Management - An OverviewThe Inventory Management Diaries

The regular supply system is a method of supply assessment for financial coverage functions in which a physical count of the stock is executed at particular intervals. This audit method takes stock at the start of a period, adds brand-new supply acquisitions during the period as well as subtracts finishing inventory to derive the expense of items marketed (COGS).They can connect a number of information points to the number, consisting of the supplier, item dimensions, weight, and even variable information, such as the amount of are in stock. RFID or radio regularity recognition is a system that wirelessly transmits the identity of a product in the form of an one-of-a-kind serial number to track items and offer comprehensive item info.

Indicators on Inventory Management You Should Know

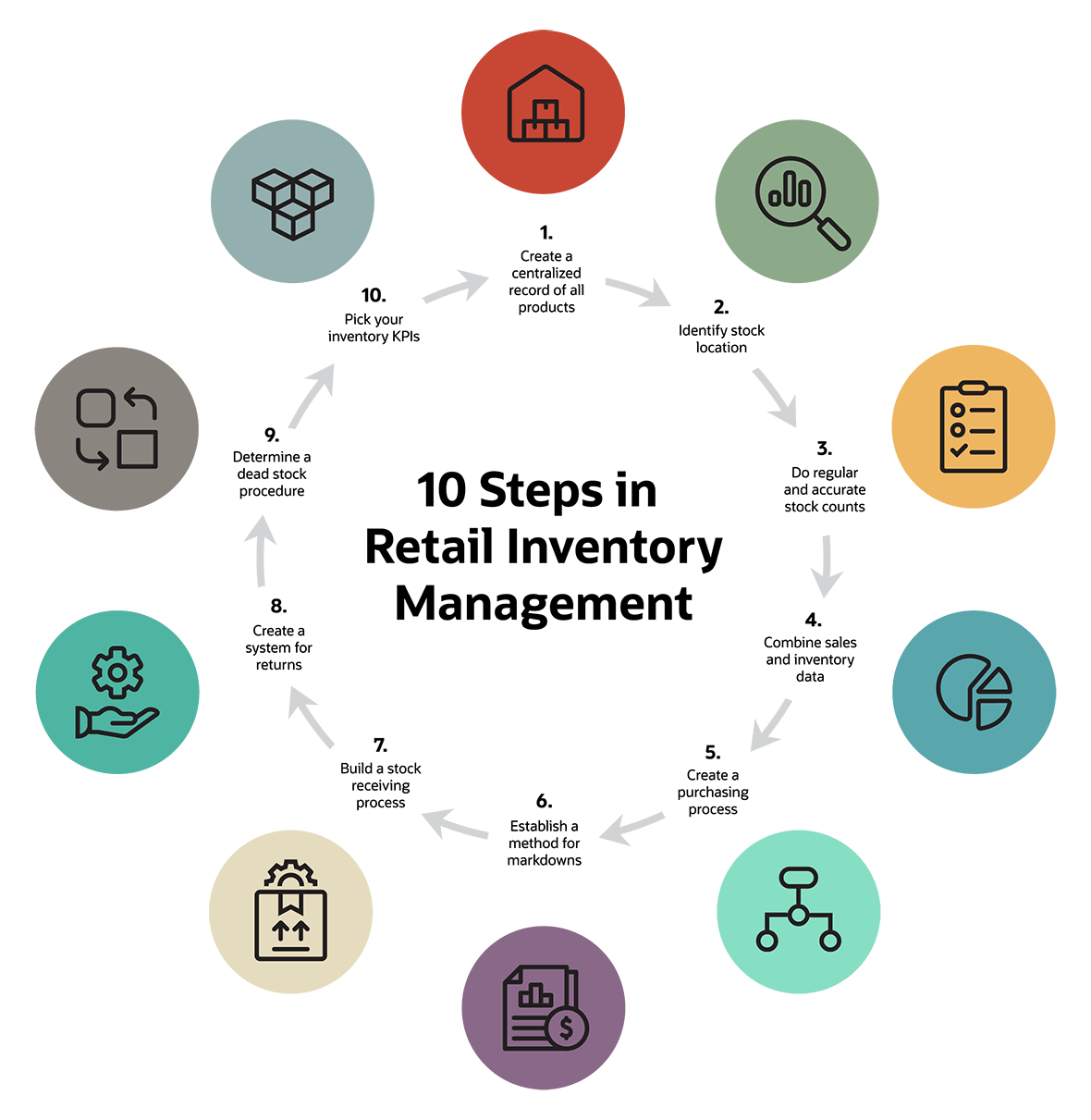

Stock management describes the process of saving, getting, as well as marketing of products as well as solutions. The discipline additionally involves the monitoring of various products as well as procedures. Among the most essential facets of inventory management is managing the circulation of basic materials from their purchase to end up products. The goal is to minimize overstocks as well as boost efficiency so that tasks can remain on time and within budget plan.

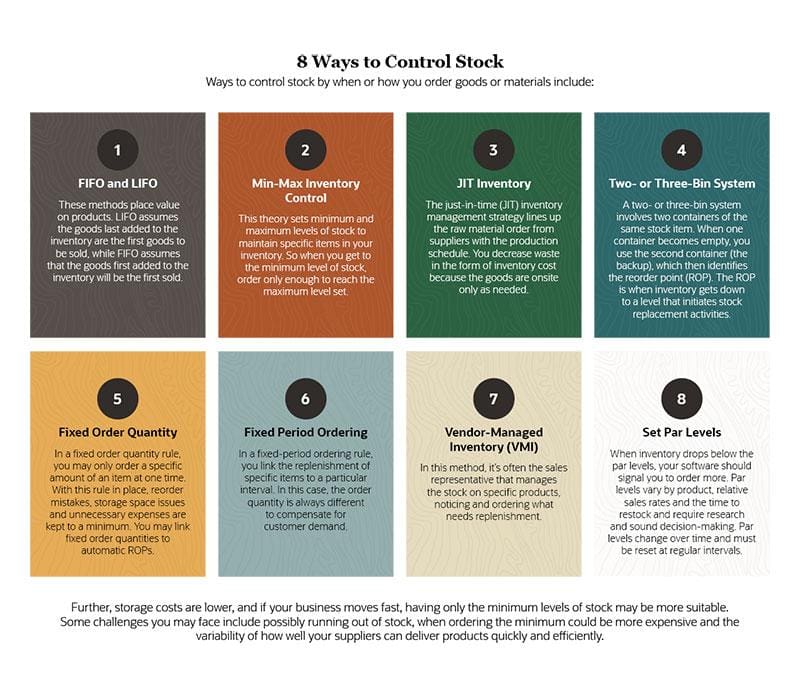

For instance, an oil depot can save a big stock for a lengthy time. Or for businesses that deal in perishable products, such as fast-fashion things, keeping top of your supply can be very expensive. One method to make up inventory is by grouping it right into 4 categories: first-in-first-out, last-in-first-out, weighted-average, as well as first-in-first-out.

Depending on the type of business that it is dealing with, different stock management methods are made use of. Some of these include JIT, material requirement planning, and also days sales of inventory.

Inventory Management for Dummies

Learn even much more about stock management from Walton University's Supply Chain Administration program's introduction on the subject covering every little thing from projecting to direct models: Among the most valuable assets of a firm is its stock. Inventory Management. In different markets, such as retail, food solutions, and also production, a lack of supply can have destructive results.

It can be vulnerable to theft, damage, and also putridity. Having a huge inventory can additionally lead to a decrease in sales. Both for small companies and also big firms, click this having a correct supply monitoring system is very crucial for any type of service. It can assist you monitor all your supplies as well as figure out the precise rates.

Balancing the threats of overstocks as well as lacks is a particularly tough procedure for firms with complex supply chains. A company's stock is generally a present property that it prepares to sell within a year.

Examine This Report on Inventory Management

Not only will it serve to boost performance, but it's likewise useful for avoiding burglary with the assistance of item tracking as well as protection. Managers can additionally intend to use their supply administration plan to keep track of sales treatments which leads to much better service.

:max_bytes(150000):strip_icc()/inventory-management-8595e839c2884128997ca77f00a8da2b.jpg)

Offering consumers several different kinds of internationally-grown produce in both natural and non-organic varieties at an inexpensive rate, even when the vegetables and fruits aren't in season, is a modern-day marvel thanks in component to supply management. Overseeing stock in actual time as well as even establishing up automated replenishment view it now systems is mission-critical to many.

The 6-Second Trick For Inventory Management

6 million plans from their brand name to third-party vendors daily. Their Smart Stockroom utilizes robot and also human assistance to do the job, but it's stock monitoring that keeps all of it rolling. According to Technology Vision, "Amazon's management strategy, together with all that automation, have made business amazingly lean and also imply by historic standards." The supply monitoring of bathroom tissue business was in the spot in early 2020 as panic-buying led to scarcities nationwide.

Below are the main types you must understand: Resources, This refers to items of your item that need to be delivered to you as well as assembled by your group. Supply systems that track these should represent provider timelines. Underway, Products made from resources and also are currently being put together or grouped fall under this category.